Planning

The planning phase of any business venture is key to the success of any product. Each piece of the puzzle including formula, packaging, branding, marketing, and distribution are vital parts of a successful product. From packaging to target demographics, our experts are here to assist you each step of the way. When getting ready to create a custom product, it’s important to consider a few questions. What makes your product different from your competitors? Will your product lines have a common thread? Who is your target customer? These questions will help guide what ingredients to use, packaging, fragrances and more.

Once you are ready to begin the process, we will have you fill out an AMR New Customer Profile. AMR will use this profile to get to know more about you and your brand. We will also have you fill out a New Product Profile for each product you want to make. This detailed questionnaire covers all aspects of your formula from color and fragrance to viscosity, performance, and budget. The more detailed the answers are, the faster the formulation process moves forward.

Formulation

With your New Product Profile in hand, our Research & Development team begins the process of building your product for you. If you have an existing formula, we will begin creating a preproduction sample for you to try.

Using the latest in cosmetic chemistry innovation, our chemists create a formula that reflects the information in the New Product Profile provided. A bench sample within your budget is created and given to you to test. After reviewing the first sample, we ask for feedback and begin to adjust the formula based off your comments.

Once you have approved the formula, we will begin the Stability and Compatibility Testing. This 3 month period will test the stability of the formula and compatibility with your packaging. Samples of finalized packaging are required for the test to be precise. If you wish to bypass Stability and Compatibility Testing, we require you to sign a waiver but will continue to run testing concurrently with your first production run.

Labeling and Packaging

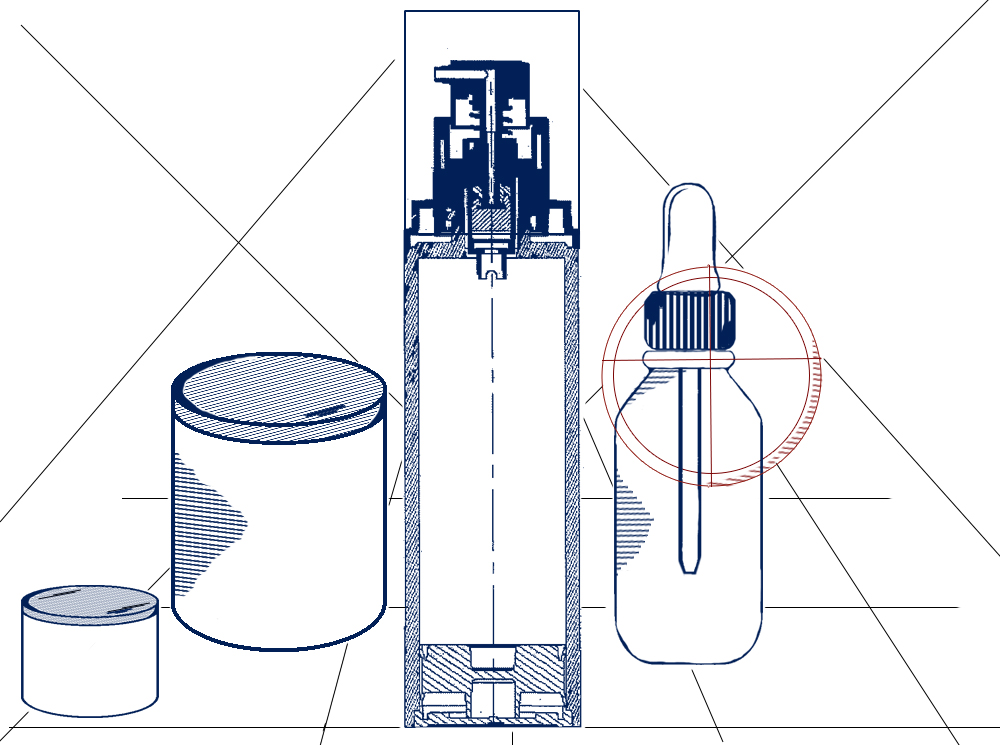

While you are undergoing the Formulation Phase, you should begin sourcing packaging. AMR Labs does not provide any packaging, however we are happy to guide you to a company that may suit your needs. Packaging is an important factor in getting your customer to pick your product over another.

We recommend scheduling an appointment to visit our showroom, which features over 100 packaging samples in different options from various vendors for packaging inspiration. AMR can refer companies to carry out your design, labels and screen printing, packaging, secondary packaging (boxes, bags, etc.). Samples of your final approved packaging will be required for Stability & Compatibility Testing.

Once you have finalized your packaging, you will place orders with the companies and have them shipped directly to our warehouse. We will warehouse packaging for products that have pending orders or have established a pattern with order history.

Production & Filling

After you have placed your order for production, we will send an invoice for the 50% non-refundable deposit. This deposit is used for our purchasing department to place orders for the raw materials for your product. Lead times vary based on vendors, ingredient location, and more. Once all components have arrived to our facility, meaning ingredients, packaging, labels, etc., we can begin the production phase. We will create large batch sizes of your approved sample. Throughout production we pay close attention and run various quality control checks, giving your products our utmost care and eye to detail.

After the completion and the QC checks of the bulk product, we will begin to fill your containers. Our filling capacity ranges from small 0.5ml sample sachets to 2 gallon sizes and more. Your product will be filled, capped, labeled, coded and sealed all in one line. After filling is completed, we will run a QC check again while putting the products into any secondary packaging (if applicable.) Your products will be packaged into case boxes and labeled for easy identification.

Shipping

There are various options for shipping your products. Shipping can be arranged by you or through our shipping coordinator. Our shipping coordinator will calculate your freight and contact multiple freight companies to get the best shipping quote. After your case packs are ready, we will calculate the final inventory count. Our billing department will adjust your invoice to reflect the final count and include shipping costs.

Your distributors may require you to ship products to multiple distribution centers. We can arrange the shipment of your products to multiple distribution centers, providing you with the proper paperwork to present to your distributor.

Products being shipped overseas will be sent through any of the various ports local to our offices including the Los Angeles Port and Long Beach Port.